How do we maintain and improve the highest quality?

Unlimited Quality Preform

PET preform product quality criteria define the PET preform production system, you can rely on

PET preform system:

- High dimensional accuracy due to high repeatability and a stable process

- Consistent preform weight and wall-thickness distribution.

- Outstanding surface quality, no scratches, highly transparent

- Low AA content and minimal material deterioration.

ShreePet Preforms and bottles are produced

- in accordance with the supplier’s specifications of raw materials,

- conform to EEC and FDA regulations.

- with all quality control requirements (cfr. General Specifications Manual)

- the raw materials do not contain heavy metals (mercury, cadmium, lead, chromium).

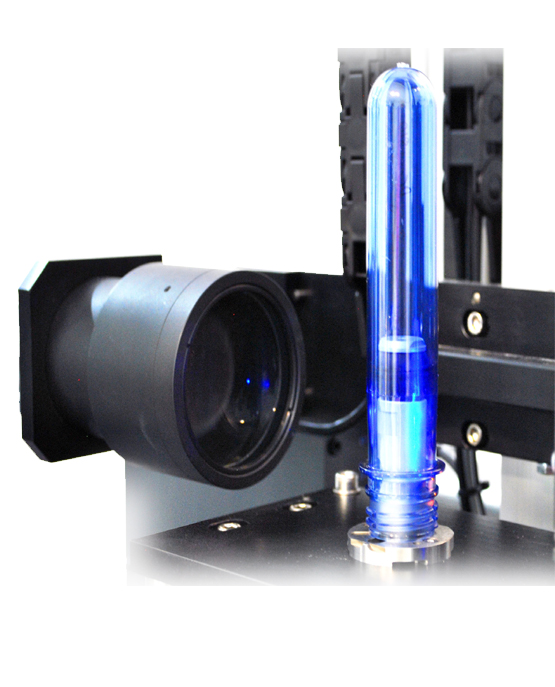

Our machines and tools are tested on regular basis to ensure their accurate performance,minimum drop of IV, maintains AA level, offers good clarity and surface gloss,uniform distribution of material and allows the blower to blow it to the fullest and achieve maximum strength to weight ratio.

Stringent quality control is implemented at every stage of production to ensure that all

PET preforms are of the highest standard.

Quality checks

- Intrinsic viscosity - Determines the strength of the final bottle.

- Physical testing - Measurements of Dimensions (length, diameters, wall-thickness,…).

- Visual and automatic control - Inspection of the appearance of our preforms.

- Color - Wide range of colored preforms are produced within narrow color tolerances.

- Microbiological identification tests

- Check of chemical traces